Content Menu

● Gathering Materials and Creative Inspiration

>> Core Bobblehead Crafting Supplies

● Designing Your Bobblehead: Concept and Proportion

>> Sketching and Digital Planning

● Sculpting the Perfect Bobblehead (Handmade Method)

● The Bobblehead's “Bobble” Mechanism

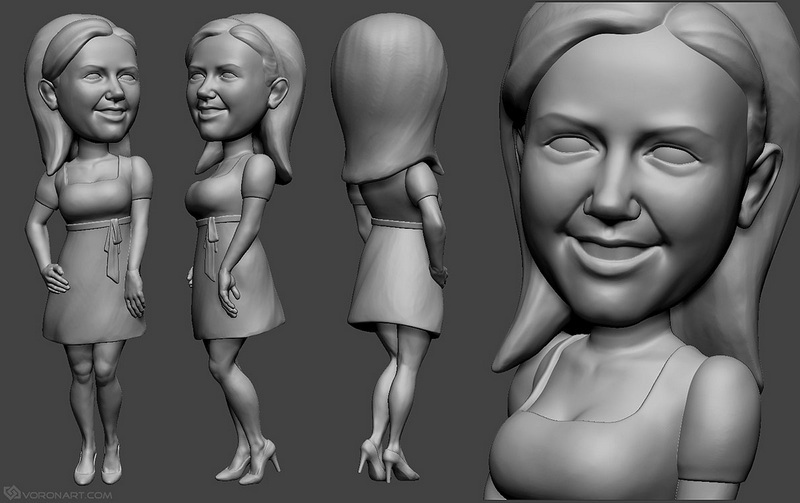

● Alternative: Digital Bobbleheads with 3D Printing

>> Step 1: Sculpt in 3D Software

>> Step 2: Prepare for Printing

● Resin Casting: The Small-Batch Manufacturing Approach

>> Steps:

● Painting, Detailing, and Finishing

● Assembly, Adjustment, and Quality Control

● Troubleshooting Common Bobblehead Issues

● Scaling Up: Making Custom Bobbleheads for Business

● FAQ

>> 1. What is the best material for a durable bobblehead?

>> 2. Can I use a regular spring for the bobble mechanism?

>> 3. What 3D printing settings work well for bobbleheads?

>> 4. How do commercial bobblehead manufacturers ensure uniform quality?

>> 5. Can custom bobbleheads be ordered in bulk for events?

The bobblehead, with its signature wobbling head and cheerful style, has fascinated collectors, artists, and sports fans for decades. While millions are sold as mass-produced memorabilia, the true joy for crafters and custom businesses is making a one-of-a-kind bobblehead from scratch. Whether you're aiming for a personal collectible, a special gift, or a small production run for a business, designing and assembling your own bobblehead is a richly rewarding project. This in-depth guide combines years of artisan expertise and the latest digital technology to show you every stage of the bobblehead-making journey—from initial design to painting, assembly, and professional finishing.[1][2][4]

- Modeling clay (polymer or air-drying preferred for hand sculpting)

- Wire (for armature skeleton)

- Sculpting tools (spatulas, carving knives, shaping sticks)

- Paints (acrylics work best for both hand and airbrush use)

- Metal or plastic coil spring (critical for head wobble)

- Glue (epoxy or superglue for durability)

- Sandpaper (320–600 grit)

- Base material (plastic, resin, or wood)

- 3D design software and printer (optional for digital method)

- Silicon molding kits and casting resin (for small-batch manufacturing)

Creative projects begin with an idea. Will your bobblehead be a humorous likeness, a team mascot, or a pop-culture caricature? Gather clear reference images from every angle, sketch a cartoonish design, and plan where to exaggerate for comedic bobblehead effect.

Draw your subject first, emphasizing the oversized head—typically almost double the body's width! Use bold lines, a playful smile, and simplified clothing or uniform details. For 3D printing, build a digital mockup in Tinkercad or Fusion 360, being sure to separate the head and body into individual files and including hollow spaces for both wobble mechanism and weight distribution.[1]

Create a sturdy skeleton from wire, shaped to the pose and base dimensions you want. Anchor this armature in your chosen base.

Add clay to the armature, building up the body's form, arms, and legs. Use reference images for anatomical cues, but exaggerate for that classic bobblehead look—short limbs, round features, and confident stance.

Roll out a large ball of clay for the head. Hollow the base of the head to create a cavity for the bobbling spring. Sculpt facial features one at a time: nose, eyes, cheeks, mouth, and hairstyle, refining with clay tools for maximum character.[2][4]

A bobblehead isn't a bobblehead until its head moves! For classic bobbling action:

- Insert a small coil spring inside the hollowed head.

- Use epoxy or superglue to attach one end firmly into the base of the head cavity.

- Secure the other end to a flat top on the neck/shoulders area of the body.

- Test the wobble: The spring should be flexible but stable, allowing the head to move freely without tipping.

Tip: Choose a spring that is just smaller than the diameter of your bobblehead's neck cavity for the best fit and optimal motion.[1]

- Use free tools like Tinkercad or advanced programs (Fusion 360, Blender) to design your bobblehead.

- Ensure the head and body are modeled separately and both are hollowed to accommodate the spring.

- Consider built-in support structures, especially for oversized heads, during design.

Export the models as STL files, slice using printing software, and set your parameters for PLA or ABS filament. Print body and head separately for clean painting and easy assembly.

Sand print layers smooth, paint if printing in plain filament, then follow the same spring installation as with the traditional method.[1]

For advanced makers or those wanting to produce numerous bobbleheads, silicone molding and resin casting offer both fine detail and efficiency.

1. Sculpt an original in clay as before.

2. Create a two-part silicone mold: place the master in a box, pour silicone, demold, and repeat to cover all sides.

3. Pour casting resin into molds to make duplicates.

4. After curing, trim, sand, and add spring mechanisms as with other methods.

Begin with a primed surface (white or grey). Apply base coats, then build up shadows, highlights, eye detail, and clothing or logo accents. Use fine brushes for facial features and decaling for complex logos or letters.

Seal the finished bobblehead with clear acrylic spray for durability and shine. Allow at least 24 hours for full curing before final display or packaging.[4]

After painting and drying, assemble the head and body with the spring as described. Test every bobblehead for optimal movement—but not so loose that heads detach easily.

For commercial batches, inspect for paint quality, assembly errors, and spring reliability.

- Head too heavy: Reduce clay or infill; hollow more space before assembling.

- Incorrect wobble: Check spring length or replace with a sturdier/finer coil.

- Paint flaws: Allow more drying time between layers and use fresh masking tape for sharp lines.

- Body base unstable: Glue a washer or small weight inside the base.

- Cracks or breakage: Use stronger armature wire and reinforce neck joints with extra clay or plastic.[8][2]

Custom bobblehead makers often accept client photos, then sculpt or digitally model heads for resin casting or printing. Factories may use CNC-milled molds for thousands of units. QC involves detailed hand-painting, protective packaging, and careful spring tuning to ensure uniform bobble quality.

Marketing tip: Offer themed collection sets—sports, weddings, graduations, company mascots—for recurring household and business revenue.

Learning how to make a bobblehead unlocks creativity, patience, and hands-on fun. Whether you choose time-honored sculpting, advanced 3D printing, or resin casting for business, the journey moves from simple supplies and sketches to a lively, personality-filled collectible. From the mildest desk gag to premium corporate promo, a bobblehead is a source of joy and community, truly coming alive with every cheerful nod.[4][1]

Polymer clay or resin are both highly durable for hand-sculpted originals; for repeat production, resin provides stronger copies and finer detail.

Yes, but sourcing the correct size is key—look for springs at hardware or craft stores, ideally just smaller than your head's base cavity for best movement.

PLA or ABS at moderate infill (10–20%) with supports enabled for overhangs; layer heights of 0.15–0.2mm yield smooth surfaces after light sanding.

They use CNC machined molds, automated casting, and strict hand-paint quality control—plus careful spring selection and mechanical testing.

Absolutely—many companies and artists offer bulk order discounts. Provide photos, theme, and brand colors for a unique, memorable keepsake.

[1](https://www.instructables.com/3D-Printed-Bobblehead/)

[2](https://www.bbobbler.com/8-steps-to-make-your-own-bobblehead-a-comprehensive-guide/)

[3](https://www.my3dselfie.com/blogs/news/a-step-by-step-guide-to-making-your-own-bobblehead)

[4](https://coupleofthings.net/blogs/coupleofthings/behind-the-scenes-how-custom-bobbleheads-are-made)

[5](https://www.youtube.com/watch?v=RN9QVyJWMaE)

[6](https://minifyme.co.uk/custom-bobbleheads-step-by-step-guide-on-how-they-are-made/)

[7](https://bobbleheadscustom.hashnode.dev/turning-photos-into-custom-bobbleheads-a-step-by-step-guide)

[8](https://www.bobbleheads.com/how-to-build-a-bobblehead)