Views: 222 Author: Mia Publish Time: 2026-01-16 Origin: Site

Content Menu

● What Is a Bobblehead Spring?

● Choosing Wire for a Bobblehead Spring

● Tools and Materials for Making a Bobblehead Spring

● Understanding Spring Size for Bobbleheads

● StepByStep: HandWinding a Bobblehead Spring

● Using a Drill to Make a Bobblehead Spring

● Shaping and Adjusting the Bobblehead Spring

● Integrating the Spring into a Bobblehead

● Tuning the Wobble of a Bobblehead Spring

● Safety Tips When Making Bobblehead Springs

● Advanced Options: PreMade Springs and Custom Designs

● FAQ

>> 1. What wire gauge is best for a Bobblehead spring?

>> 2. How long should a Bobblehead spring be?

>> 3. Do you need special tools to make a Bobblehead spring?

>> 4. Can premade springs be used in a Bobblehead?

>> 5. How do you stop a Bobblehead head from leaning?

A Bobblehead spring is the core mechanism that gives a Bobblehead its fun, nodding motion. By making a Bobblehead spring yourself, you can control how far the Bobblehead head wobbles, how soft or firm it feels, and how durable the whole Bobblehead structure will be. With simple tools like wire, a dowel, and pliers, you can create reliable Bobblehead springs at home for wooden, plastic, clay, or 3Dprinted Bobblehead projects.

A Bobblehead spring is a small helical compression spring or tightly wound wire coil that connects the Bobblehead head to the body and flexes when the head moves. When someone taps or shakes the Bobblehead, the spring compresses and bends slightly, then returns to its original shape, causing the head to wobble for a few seconds before settling. In most Bobblehead designs, this spring is hidden inside the neck cavity, but its size and strength are critical to the final effect.

The wire you choose determines how strong, flexible, and longlasting your Bobblehead spring will be. For hobbylevel Bobbleheads, you do not need industrial spring wire, but the wire must still be resilient.

- Music wire or highcarbon spring wire offers excellent strength and returns to shape after repeated bending.

- Many DIY Bobblehead makers use craft or jewelry wire in the range of roughly 18–22 AWG for small to medium figures.

- Thicker wire (lower gauge) makes a stiffer Bobblehead spring that supports heavier heads but wobbles less.

- Thinner wire (higher gauge) makes a softer Bobblehead spring that wobbles more but can deform if overloaded.

Commercial Bobblehead springs are often made from steel wire with a diameter under 1 mm, tuned to the size and weight of the Bobblehead head and body.

Making a Bobblehead spring requires only a simple set of tools, many of which are common in home workshops or craft rooms.

- Spring wire or strong craft wire (music wire, steel wire, or strong jewelry wire)

- A mandrel such as a drill bit, metal rod, knitting needle, or wood dowel, sized close to your target spring inner diameter

- Hand drill or electric drill (optional, for fast and even winding)

- Pliers for gripping and bending wire ends

- Wire cutters for trimming the spring to length

- Ruler or calipers to measure Bobblehead spring length and diameter

- Safety glasses and gloves, especially when cutting or handling stiff wire

For basic Bobblehead projects, many crafters simply wrap wire around a pencil or dowel by hand and trim the coil with pliers. More advanced makers use a small drill or lathe to wind consistent, highquality Bobblehead springs.

Before winding a Bobblehead spring, it helps to define the size so it fits cleanly inside the Bobblehead head and body cavities.

Key size factors:

- Inner diameter: The open center of the spring, which must fit onto any peg or into the drilled hole in the Bobblehead head and body.

- Wire diameter: The thickness of the wire, which controls how stiff and strong the Bobblehead spring will be.

- Free length: The total length of the spring when not compressed; this sets how much movement is possible.

- Number of coils: More coils generally make the Bobblehead spring more flexible for a given wire size and diameter.

For small desktop Bobbleheads, a spring inner diameter around 8–15 mm is common, with a length of about 20–40 mm depending on the head size and desired wobble. Heavier, carved or resin Bobblehead heads need shorter, thicker springs to hold their weight, while lightweight plastic or 3Dprinted heads can use longer, slimmer springs for more dramatic wobbling.

Handwinding is the simplest method for making a Bobblehead spring and works well for prototypes and oneoff projects.

1. Prepare and cut the wire

- Measure the approximate length you need for your Bobblehead spring, adding a few extra centimeters for end tails.

- Cut the wire with wire cutters and gently straighten it by pulling and rolling it on a flat surface.

2. Secure the wire to the mandrel

- Choose a mandrel (such as a drill bit or dowel) slightly smaller than your target spring inner diameter.

- Bend one end of the wire around the mandrel and pinch it tight with pliers so it will not slip while you wrap.

3. Wrap the coil

- Hold the mandrel in one hand and the free wire in the other, keeping steady tension as you turn.

- Wind the wire in tight, even coils, keeping the turns close together without overlapping.

- For a Bobblehead spring, aim for uniform loops so the head moves smoothly and does not lean.

4. Create end tails

- When the coil is long enough, bend the wire sharply away from the mandrel to create a short straight tail.

- This tail will later insert into the Bobblehead head or body to anchor the spring in place.

5. Remove the spring and trim

- Slide the coil off the mandrel slowly, being careful not to deform it.

- Trim any extra length from the ends, leaving tails long enough to glue or embed into the Bobblehead structure.

By practicing this handwinding technique, you can quickly make Bobblehead springs of different lengths and stiffness for different figurines.

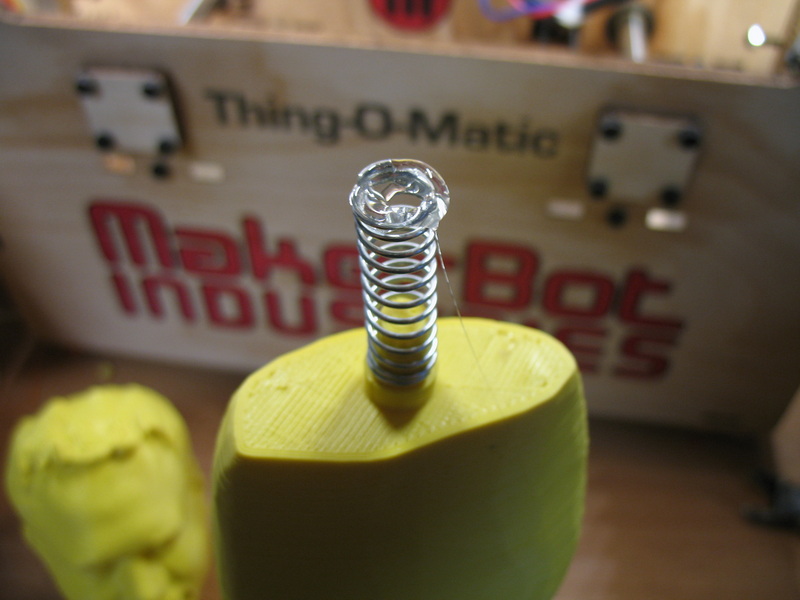

A hand drill or electric drill helps create more consistent Bobblehead springs with less effort, especially if you plan to make many Bobbleheads.

- Clamp the mandrel (such as a drill bit or rod) in the drill chuck, leaving enough length exposed for the spring.

- Secure one end of the wire to the mandrel by bending or clamping it so that it will not slip.

- Hold the wire in gloved fingers or pliers and run the drill slowly so the mandrel pulls the wire into a tight, even coil.

- Stop as soon as the Bobblehead spring reaches the desired length, then cut and remove the coil.

- Cool the wire if it becomes warm from friction, and always wear eye protection.

This method gives uniform coils and saves time when making multiple Bobblehead springs for a series of figures or for small production runs.

After winding the spring, some adjustments can improve the Bobblehead wobble and fit.

- Flatten the ends: Use pliers to gently press and flatten the outer coils so the Bobblehead spring has flatter seating surfaces.

- Add or remove coils: If the Bobblehead head feels too stiff, carefully stretch the spring or remake it with more coils; if it is too loose, compress the spring or remake it with fewer coils.

- Adjust tail length: Bend the end tails to fit snugly into drilled holes in the Bobblehead head and body without bottoming out too early.

- Correct minor bends: Straighten any unwanted kinks so the Bobblehead head sits upright instead of tilting.

These small changes can transform a rough coil into a reliable Bobblehead spring that offers the right mix of stability and playfulness.

A Bobblehead spring must be mounted securely between the head and the body so it can flex without breaking loose.

- Drill or sculpt a cavity in the top of the Bobblehead body sized to grip the spring or its tail.

- Drill a matching cavity in the bottom of the Bobblehead head, aligned with its center of gravity.

- Push one end of the spring into the body and the other into the head, testing the fit dry before adding glue.

- Use a strong adhesive suited to your Bobblehead material (wood, resin, plastic, or clay) to secure the spring once you are happy with the movement.

- Allow glue to cure completely before stresstesting the Bobblehead.

Some woodcarved Bobblehead designs use a peg on the body and a spring that fits over the peg, while the head connects to the other end of the spring through a similar peg, creating a simple but robust joint.

The personality of a Bobblehead depends heavily on how the spring behaves. You can tune the wobble by adjusting several variables.

- Spring length: Longer springs give a larger, slower wobble; shorter springs feel snappier and more controlled.

- Wire thickness: Thicker wire makes the Bobblehead more stable but less responsive; thinner wire increases motion but can sag under heavy heads.

- Head weight: Adding or removing weight from the Bobblehead head changes how much the spring compresses and how long it oscillates.

- Attachment depth: A deeply embedded spring is more stable, while a shallow attachment allows more swing but can stress the glue joint.

Test the Bobblehead by tapping the head lightly from different directions. A welltuned Bobblehead spring should allow several smooth oscillations without the head hitting the shoulders or the figure falling over.

Making and installing a Bobblehead spring involves sharp wire and tools, so safety is important.

- Always wear eye protection when cutting or winding wire, as small pieces can snap or fly.

- Use gloves when handling stiff wire to avoid cuts and to improve grip on the Bobblehead spring.

- Keep small springs and cut fragments away from children and pets.

- If using power tools like drills or small lathes, secure workpieces properly and keep fingers clear of moving parts.

By respecting the tools and materials, you can build Bobblehead springs safely and confidently, even in a small home workspace.

In some cases, buying premade springs or designing custom ones may suit your Bobblehead project better than handwinding.

- Premade compression springs: Hardware and online stores sell small steel compression springs that can be adapted for many Bobblehead designs.

- Coneshaped springs: Some Bobblehead dolls use tapered or cone springs that compress in a unique way and can help with stability.

- CADbased spring design: For massproduced Bobbleheads, engineers calculate spring constant, coil count, and wire diameter precisely to match head weight and user expectations.

- Hybrid mechanisms: Some modern Bobbleheads combine springs with flexible plastic hinges or ballandsocket joints to create more complex movement.

These options are especially useful when producing a series of Bobbleheads, where consistent wobble from figure to figure is essential.

A Bobblehead spring may be hidden inside the neck, but it is the key component that makes a Bobblehead come alive. By selecting suitable wire, winding a neat and consistent coil, and integrating the spring carefully into the Bobblehead head and body, you can create a wobble that feels fun, stable, and durable. Whether you are customizing a single Bobblehead, building a collection, or developing products for fans and customers, mastering the Bobblehead spring gives you precise control over how each nodding figure behaves and delights people.

Contact us to get more information!

For most small to medium Bobbleheads, wire in the range of about 18–22 AWG offers a good balance between strength and flexibility. Heavier Bobbleheads may need thicker wire to keep the head upright, while very light heads can use thinner wire for more dramatic wobbling.

A typical Bobblehead spring is long enough to allow visible wobble but short enough to keep the head controlled, often somewhere around 20–40 mm for small desktop figures. The ideal length depends on head weight, wire stiffness, and how much neck clearance the Bobblehead has.

No special machinery is required for simple Bobblehead springs. A dowel or drill bit, basic pliers, wire cutters, and optional hand drill are usually enough to make clean, functional springs. More advanced setups like small lathes are helpful but not necessary for most hobby projects.

Yes, premade compression springs from hardware or online suppliers can be used as Bobblehead springs as long as the diameter, length, and stiffness match your design. Many makers build their Bobblehead head and body cavities around a standard spring size to simplify sourcing and assembly.

If a Bobblehead head leans to one side, the spring may be bent, too soft, or installed offcenter. Straightening or replacing the spring, using a slightly thicker wire, deepening the mounting holes, or adjusting the head's internal weight can help the Bobblehead sit upright and wobble evenly.

1. https://www.youtube.com/watch?v=jAawhg6JtyY

2. https://www.instructables.com/Make-your-own-springs-in-seconds/

3. https://www.youtube.com/watch?v=ubQqYq5vmnc

4. https://www.hobby-machinist.com/threads/spring-making-from-music-wire.85853/

5. https://www.youtube.com/watch?v=xZMmAcp7cc0

6. https://www.youtube.com/watch?v=DOGcpoSFUCw

7. https://www.thespringstore.com/standard-spring-wire-diameter-sizes.html

8. http://www.deansphotographica.com/machining/projects/springs/springs.html

9. https://www.youtube.com/watch?v=b_FrrllTHqs

10. http://carverscompanion.com/Ezine/Vol8Issue6/JOharra/JOharra.html

11. https://www.youtube.com/watch?v=Us28iaPOitU

12. https://www.instructables.com/3D-Printed-Bobblehead/

13. https://www.alibaba.com/product-detail/Wholesale-Steel-Cone-Shaped-Wire-Springs_1601053823299.html

14. https://www.mig-welding.co.uk/forum/threads/making-small-compression-springs.102521/

15. https://www.facebook.com/TLCCrafters/videos/bobble-head-springcoil-instructions/751667295819770/